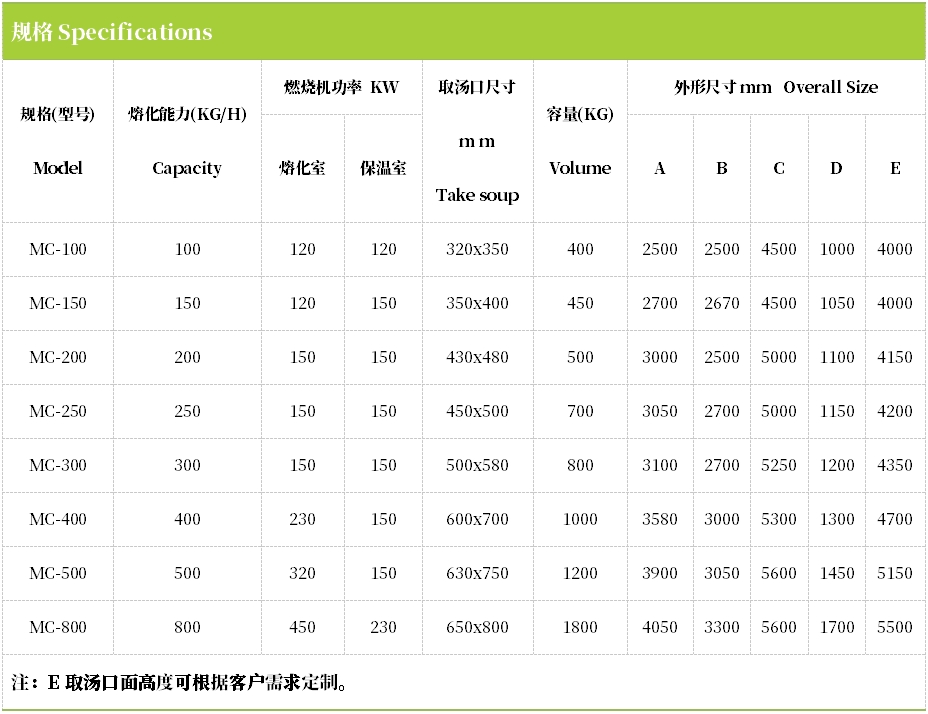

This system is specialized in aluminum melting and temperature preservation. It is a tower structure,w ith continuous melting, automatic feeding. High automation, high heat efficiency, low burnout loss and long service life. Split type proportioning burner makes it easy to control temperature in set range. Th oxide is controlled in minimum level, it further reduces oxidation loss.

System Highlights

> Proportional burner ensures full combustion and no excess oxygen, this minimizes oxidation loss and slags.

> Hot tail gas is reused for preheating new combustion air. It reduces energy loss and improves thermal efficiency.

> Furnace chamber is neat designed for easy cleaning.

> Full automatic feeding system includes material lifting, furnace cover opening, material dropping and furnace cover closing are all controlled by PLC system. This computer controlled system is advanced and reliable.

> Simplified operation, both molten aluminum and air temperature were controlled separated. The liquid temperature is within +/-5 Celsius degree.

> The furnace liner is built with high grade imported seamless cast material. This non-aluminum-sticking material is with over 8 years service life and without corundum skull.

Ruian Jingxing Machinery Technology Co.,Ltd