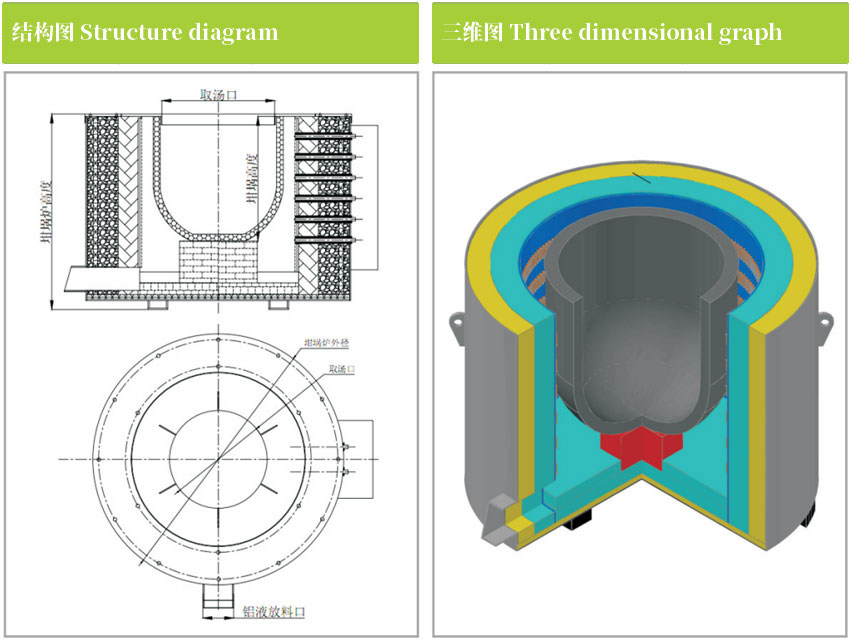

The EC type crucible furnace uses high quality electric resistance in heater unit, mainly for Aluminum ally melting and insulation. System is suitable for die casting, dip casting, degassing and slag removing for liquid die forging, alloy preparation, structure homogenizing, temperature adjustment.

System Highlights

> High quality for precise requirement. Such as accurate temperature and homogenized aluminum liquid.

> Accurate and reliable temperature control. Direct and high accuracy control to molten aluminum temperature is achieved by employing advanced PID control technology with intelligent temp control device and temp measuring thermocouple specialized for aluminum liquid.

> Aluminum liquid temperature is even, no extreme high temp on portion. Heater is detached from aluminum liquid and distributed evenly on along the crucible. The temp on along the crucible height direction is even, this ensures heat evenly distributed.

> Less burnout loss. Heating module is detached from aluminum. Thermo is evenly conducted thru crucible to avoid extreme high temp on portion. This reduces the burnout loss and high temp volatilization. Alloy burnout loss is less than 1.2%.

> Completed alarm & protect system. The alarm system monitors liquid over temp, chamber over temp and liquid leaking. the system can automatically cut off power to protect the system from further damage.

> The heater service life is over 2 years. When applying comprehensive control technology such as period alternating and PID, and improve the heating module design, the service life could be elongated more than one extra year.

> Furnace chamber inner wall is built with high refractory material, full fiber structure with multiple type insulator. Perfect insulator, quick temp increase, high efficiency. The body outside wall temp increase less than 15 Celsius degree than environment.

Ruian Jingxing Machinery Technology Co.,Ltd